0

What do I have to do to disable the safety switch so I can remove the sidestand off an '09 CBR 600?

track bike only

solder the two wires together

Gino

HAWK GT Racer Expert #929

2012 CCS LRRS ULSB Champion

2012 CCS LRRS P89 Champion

2008 CCS ULSB National Champion

ECKRACING Bridgestone Street & Competition Woodcraft MOTUL On Track Media Pine Motorparts Vanson Leathers

Thanks guys!

There are less permanent ways to do this, as I've gone both routes, trimming a harness for just what I need, and keeping them whole. I find it's better to leave them whole. I have all the un-needed plugs tucked away and ziptied somewhere, but dont cut them anymore.

If your harness side of the plug is female, I recommend:

use a jumper wire and male pins to jump the switch. If the plug is deep enough, you can fill it with silicon that will harden and keep things dry, otherwise you can use heat shrink or tape over the plug to keep things clean.

If your harness side of the plug is male (or you don't like the above suggestion):

Use a "splice connector" that piggy-backs one wire, and lets you add one. Use a blade or drill bit to remove the hard stop that is used to but the additional wire to in normal use, and now you have a clip that will splice two parallel wires together. As above, heat shrink, tape, or silicone your plug.

My .02, if it's for track day use I'd consider just keeping it on there for convenience.

For racing, yeah, needless weight. See posts above.

-Pete

NEMRR #81 - ECK Racing

Cyclesmith Track Days

Woodcraft | MTag-Pirelli | OnTrack Media

'03 Tuono | '06 SV650 | '04 CRF250X | '24 Aprilia Tuareg

What ever happened to unplugging things and using a jumper wire instead?

Alls I'm saying is there are connectors of all kinds out there which can be used for making a jumper. Chopping and soldering wires is an absolute last resort, IMO.

have you seen your bike?

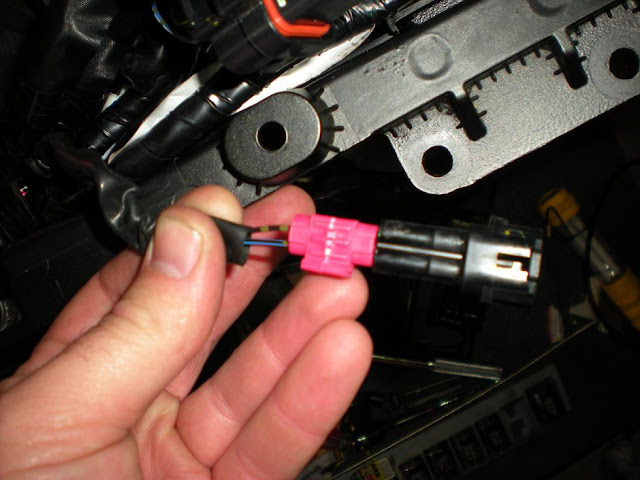

btw, that connector method I showed in the jpeg is pretty nice... especially because with a soldering iron, the insulation can be put back together if you ever decided to remove it.

but lets say you spent unecessary money on an extra kickstand sensor, or scrolled through japanese catalogs of plastic connectors and found one... how exatly does the jumper get installed in a way thats better than solder?

I thought I was anal, but this I have to hear...

Kitt has a great solution to this... I'd just listen to him and be done with it.

The best advice Iíve ever been given is to not forget where you came from.

Did I chop any one of those wires? I've corrected everything that I'm able to just short of buying a new harness.

I'm not saying your method isn't good, I'm saying chopping and soldering is the last resort. Again, IMHO. It's what I do for work and that's why I don't see chopping and soldering as a viable option.

Here are some examples of what I'd use. This is just a quick grab of what I have. There are about 4 more styles in additon to these that are in my tool box.

those are the ones I suggest, also... for female harness. Now, for a male harness where this will leave the jumper outside of the plug, what do you do? just let the loop dangle out there? I like the wiring tucked away.

The methods I use, are using the pieces you showed, or using that clamp-on type... now, since you do it daily. what's wrong with the clamp-on type?

P.S. I usually trust solder more than crimped connectors, when running my own wiring... but settle for your connector types, when I am trying to leave a current harness as-is.

Kitt, I didn't say anything was wrong with the clamp-style connector you use......hell, I don't even recall saying that chopping and soldering is wrong. I attempting (and failing) to convey other options that are easily removable and correctable over and above chopping and soldering a wire harness, something which everyone seems to love doing, not just racers. Hey, it's easy and there's no denying that.

Anyone wants to chop and solder, have at it. I really don't care. Just know there are other ways to make a proper and reliable connection that don't impact or alter the wire harness nearly as much. It involves a little extra work but who wants to do that when it's so much easier to snip and twist?

Another OEM style plug that could be clipped and soldered and heatshrink wrapped would be ideal. Then the bike is easily converted back to stock configuration easily. But that is not practical. I think what Woody wants to know is if there are only 2 wires in the harness to the sensor or if there are more and if so which colored wires that would need to be wired to complete the circuit. Myself I would prefer it soldered and folded up under the way and zip tied in place. Only for reliability. Would not want the bike to miss a race cause of corosion or you lost the pin, etc.......This could be a business opportunity. Make plug-in connectors for kickstand bypasses for most sportbikes.