1

hmm, clipped a ground wire off the starter relay plug and shouldn't have. FAIL. NO FIRE. harness is back off. think i'm going to ditch all the single connectors and go to multi-wire waterproof plugs. with the weather turning shitty again, might as well keep improving.

that race harness is looking like a bargain now

Beta 200RR

Cliff's Cycles KTM

NETRA enduro B-vet

Close your eyes, look deep in your soul, step outside yourself and let your mind go.

should be good after reconnecting that ground wire. the system is pretty simple but the grounds were ganged up in a few locations that made it tough to know if they were just for lights or more important. only other unknown wire was a yellow/red that ended up being for a dual-map switch but my CDI is single map only. bummer. would have been nice to sampe the 'soft' map on the slickery days.

i'll feel better about the whole job if i move to these style connectors in 2-pin and 3-pin formats:

also going to cut out the crimped unions and move to solder splice sleeves.

i should have just ordered from the get go but didn't want to cut any OEM connectors out. now i don't care since i already cut some out, e.g. start/kill blocks. i'll be able to shorten the entire harness to exactly what i need. some leads are longer than they need to be requiring a bundle inside the frame. i can chop some of that wire out.

Beta 200RR

NOW i feel better about this job. got my upgraded plugs, shrink wrap and sheathing. OEM spec stuff from CycleTerminal.com in Jersey. great selection and service.

bar switch plug > harness is the 4-pin and the 3-pin carries wiring back to the starter relay. repaired the ground wire i snipped off the starter relay and ran it back up to the ground junction > coil.

these plugs are sealed with rubber grommets and the shrink wrap has adhesive inside that melts to form an even better bond. love it.

had some discussions and did some research on my new spring setup. consensus is i would be out of balance with .44 up front and 5.6 out back, too stiff in rear even though my sag numbers looked great. last Sachs spring i rode was a 5.35 so i decided to try a Racetech 5.4 because their rates are more accurate AND linear through full travel, unlike the Beta/Sachs springs.

the RT spring is wider by 5mm and quite a bit longer. will be a tight fit to the shock reservoir and air boot. it's not uncommon to run these though so i'm not expecting any issues. very curious how preload + sag will shake out.

Beta 200RR

Have you been attacking those spring preload collars with a dull beaver?! For shame, an adjustable spanner is only like $35!

hahaa, i was waiting for someone to noticei adjust with my OWN TEETH. no beaver.

Last edited by typeone; 03-14-18 at 05:27 PM.

Beta 200RR

Better then the old school flat screwdriver and hammer method.

yeah, very small 'window' to work with on my shock as well. it looks more beat up than it is due to dirt in between, and some Sharpie markings during testing, but it is pretty hacked up. i don't sweat it, that's what the notches are there for. no way i could fit a spanner while it's on the bike.

i did upgrade to a Motion Pro shock punch with brass angled tip, very nice. bought it more for the reach than to save the preload rings.

Beta 200RR

Are you crimping pins and assembling the connector or getting them as pigtails and soldering to those?

yes, thanks, the wiring i'm using the plugs for is very light guage.

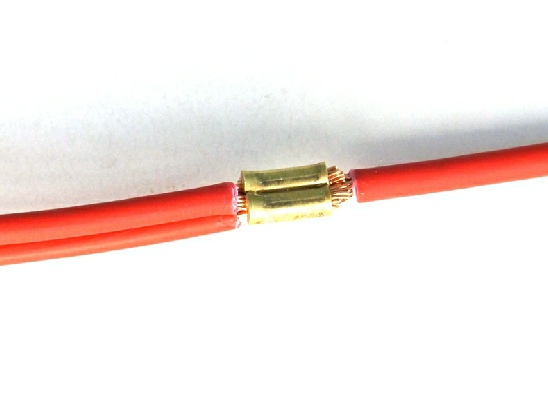

strip > crimp x2 > assemble, no pigtails. i bought a specific crimper for the pin types. first is wire crimp, second is seal crimp. you end up with this before snapping into the connector body:

wish i saw that he had splice terminals, could have saved me some soldering at multi-wire junctions!

Beta 200RR

another strikeout ... Racetech spring doesn't fit. just barely interferes with the reservoir even with the correct adapter ring. not feelin' it

ordered a Cannon Racecraft instead, spec is exact to OEM Sachs.

Beta 200RR

I'm sure it would self-clearance in couple of rides.

I went to MMI I know what Im doing here chief

yeah, thought about that or just grinding the reservoir body a bit but i think more clearance will be better in the long run. Cannon was quick and easy to work with, i've heard very good things about their springs and customer support.

here's the reason why i'm trying something other than another OEM spring, check out these test results below. not only is it a crap shoot what you get (unless you have it tested first) but you don't hit the springs full rate until the bike is sacked out. i'm trying to keep this thing up higher in the stroke without going too stiff. should help improve feel through the gnar.

what the above highlights is that your static/race sag wouldn't be accurate. you would end up going with a stiffer spring to get the numbers you're after.5.4kg spring direct from Beta

0-30mm compression 5.0

30-50mm compression 5.1

50-70mm compression 5.2

70-90mm compression 5.3

90-110mm compression 5.4

The problem here is that the shock shaft only has 133mm of travel and typically 8-10mm of preload on the spring. This means that the bike won’t see the 5.4 rate until the last 1/3 of the travel.

the 5.6 i had on there (but hadn't ridden yet got it in a free trade) had great numbers. 30 static, 96-98 race, 9mm preload, 248mm free length. this is prime stuff for the Beta but shit, i wonder what the rate would feel like at 70-90mm compression (?)

Last edited by typeone; 03-15-18 at 07:22 PM.

Beta 200RR

Linear spring

Y u no linear?!

'02 Ducati 998, '08 Ducati HyperMotard 1100S, '14 Subaru XV Crosstrek

I cringe a little at those crimp joints. But then I hear they are actually superior for high vibration uses, like motorbikes.

has no compute (?)

i would have rathered those (+ adhestive shrink wrap) over solder for durability. that crimp tool i bought is sweet, makes those nice folds, looks factory fresh and secure.

i'm hoping the regulator wires do OK, they were looking kinda beat already. contemplated just redoing that joint > plug now that i know what i would need. i've got a bunch of spare wire i could use, just need the male 4-pin connector.

Beta 200RR

Vibration causes cracks and breaks at solder joints, that's why you'll never see solder joints in proper vehicle wiring harnesses. A proper crimp connection is solid. Heatshrink over it provides environmental protection.

yup, that's what i'm afraid of but i'm sure it will be fine, the three small solder joints are cushioned in a wrap of wire zip tied to an open triangle in the frame, doubt they would fail ... BUT now that i've done this TWICE, i'm tempted to make the ENTIRE harness again. hahaa. gets better each time ... and you know what they say about the thrid time

Beta 200RR

If it makes you feel better, my motard is chock full of solder. I'd love to borrow that crimper setup and redo it some day.